Honing

We offer very precise honing of cylinders and shells, also plateau from 70 to 250 mm in diameter, up to 500 mm in engine blocks and other units.

The works are performed on the ROTTLER H85A (ASV) CNC honing machine.

Honing

Honing is one of the most precise ways of drilling hollow circular shapes. Different types of diamond and abrasive tips are used for honing. In the process of honing processing, high accuracy of bore geometry and the required surface roughness are achieved.

When honing with a ROTTLER H85A machine tool, the cylinder geometry is automatically controlled and adjusted. This results in a much more accurate opening compared to other honing machines or grinding methods.

Thanks to the wide selection of honing stones compared to grinding wheels, it is possible to perform tasks more accurately in accordance with technical requirements and achieve the best results.

Through honing it is possible to obtain the necessary micro-relief, groove indentation, immersion and peak ratio (plateau honing), opening of graphite layers in cast iron is achieved. All this is not possible with conventional grinding.

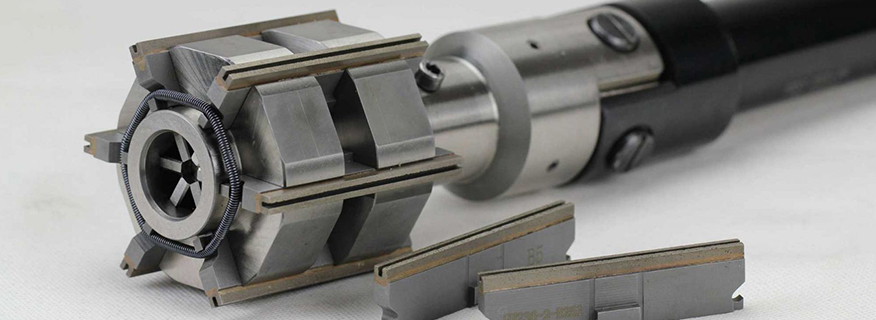

Plato honing

Plato honing or flat surface honing – is known from long ago, still from aviation piston engines. The idea is also found wider application in the automotive engine industry.

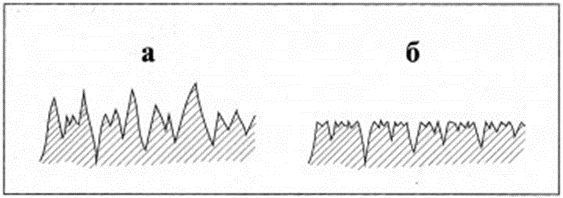

As a result of classical honing, we obtain a microplate of the cylinder work surface, which resembles a mountain range with sharp points (figure, a). During the initial period of operation (on approach), these protrusions level out until sufficiently large bearing surfaces are formed. It is much more logical to immediately reach a surface (figure, b) as a result of the treatment, which ensures the continued correct operation of the engine.

Pros of the Plato honing method.

Highly precise machining of engine cylinder and shell geometry provides micro-relief for further work, as a result of which the engine shell and piston rings work faster, in general, parts wear less.

As a result of fast operation, the compression in the cylinders increases, oil consumption decreases, gas leakage into the crankcase. All this has a positive effect on the use of engine resources until the next overhaul.

We honing the flat surface using our modern honing machine ROTTLER H85A with computer control.